Maximizing Your Warehouse Storage

Every successful business understands the importance of efficient warehouse storage. As trade and commerce evolve, businesses are faced with increasingly dynamic demands, and having a flexible, well-organized warehouse is pivotal. The most significant challenge, however, often lies in utilizing every inch productively. This issue is compounded by the constant pressure of maintaining operational costs, syncing with supply chain requisites, and ensuring the smooth running of warehouse services. How then can one maximize warehouse storage without expanding square footage? This blog post aims to explore smart strategies to enhance your warehouse storage. This blog will introduce you to the key tenets of warehouse storage and offer innovative solutions to common bottlenecks in storage functionality.

Understanding the Basics of Warehouse Storage

To begin tackling warehouse storage challenges, understanding the basics is our first step. A warehouse, at its core, is a storage system designed to accommodate goods from a point of origin to a point of consumption. The main aim of warehouse storage is the efficient securing and handling of products until they are needed. The essence of this concept lies in managing the storage space effectively, as inadequate or disorganized storage capacity can heavily affect warehouse operations, impacting both time and financial resources.

Different variants of warehouses exist, from large companies’ distribution centers to smaller, commercial storage facilities. Overall, the central demand is efficient space utilization, regardless of the warehouse’s size. Ideally, every square foot of a warehouse should be effectively used to store items and facilitate straightforward, speedy access—a concept known as direct access.’

One prime component of this is the type of storage units or racks deployed within the warehouse. These units vary from static shelving, traditional and commonly used for easy access, to mobile shelving, moving along rails installed in the floor to reduce unused aisle space. Similarly, ‘pallet rack’ is another term you might come across frequently—these are stand-alone frames that can hold pallets, enabling high-density storage.

Today, handling modern warehouse complexities calls for more than just efficient storage units but also systems that oversee these operations. The warehouse management system (WMS) is a system designed to support and optimize warehouse functionality from stock location and counts, and space utilization to order fulfillment.

In essence, managing warehouse storage is just as much about these infrastructure elements as the strategies employed to use them. Warehouse operations’ efficiency, therefore, lies in making these elements work in tandem to offer an optimal storage solution.

The Core Principles: Strategies to Maximize Your Warehouse Storage

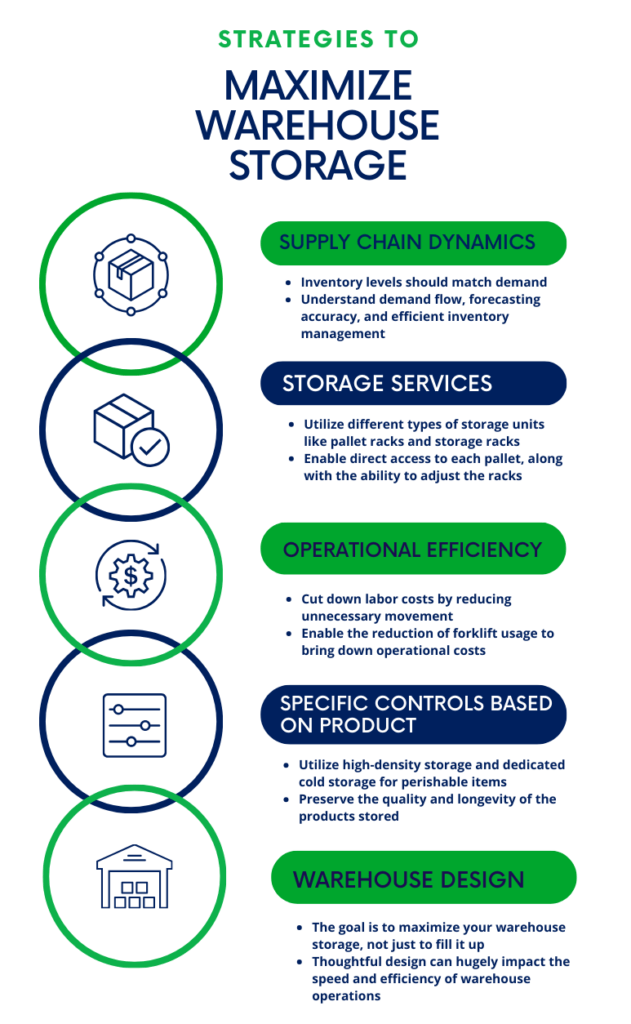

Now that we’ve grasped the basics of warehouse storage, let’s delve into the core principles that can help you make the most out of your existing warehouse space. Making strategic changes to your warehouse operations can lead to surprising improvements in your storage capacity and operational efficiency.

The key lies in understanding the role of the supply chain in warehouse management and incorporating space optimization strategies in your storage system.

Supply Chain Dynamics

Supply chain dynamics greatly influence how you manage your warehouse. Inventory levels should match demand to prevent excessive stock accumulation. This requires an understanding of demand flow, forecasting accuracy, and efficient inventory management. High-demand items should be placed strategically to ensure that access is not impeded, leading to quicker fulfillment cycles.

Storage Services

Different types of storage units like pallet racks and storage racks can significantly enhance your warehouse’s storage capacity. Pallet racking systems, in particular, can transform your warehouse storage by offering high-density storage in a small footprint. Direct access to each pallet, along with the ability to adjust the racks according to the size and weight of the goods, makes these systems extremely versatile.

Operational Efficiency

The importance of operational efficiency cannot be undermined in warehouse operations. Cutting down labor costs by reducing unnecessary movement, and managing storage rack accretion are strategies worth considering. A well-planned warehouse could even enable the reduction of forklift usage, further bringing down operational costs.

Specific Controls Based on Your Product

If your warehouse deals in perishable goods or items that require specific temperature controls, utilizing high-density storage, and dedicated cold storage warehouses can be a game-changer for your storage solutions. A cold storage warehouse provides a temperature-controlled environment, preserving the quality and longevity of the products stored.

Warehouse Design

And lastly, don’t underestimate the importance of warehouse design and layout. Thoughtful warehouse design can hugely impact the speed and efficiency of warehouse operations. Remember: the goal is to maximize your warehouse storage, not just fill it up. By keeping these principles in mind, you can effectively increase your storage space and improve warehouse efficiency. So, think strategically, think efficiently!

Warehouse Storage Solutions Examples

Industry leaders have long found creative and often unconventional ways to maximize their warehouse storage. Let’s discuss some successful strategies implemented by various commercial entities, illustrating the adaptability of warehouse solutions in different scenarios.

Take a home furniture giant that needs more space in its warehouse. They could utilize a high-level racking system within their warehouse. Transforming vertical space into practical storage areas would increase their storage capacity while maintaining direct access to all inventory, saving them from investing in additional warehouse space.

Another example is an e-commerce business that employed mobile shelving in its warehouse. Given the dynamic nature of e-commerce and the need for a versatile inventory, they innovatively used mobile shelving to accommodate variability. This choice not only maximized their storage space but also enhanced their fulfillment speed.

On a larger scale, a multinational company could use insulated panels to maintain a temperature-controlled environment and successfully store temperature-sensitive products. This allowed the company to utilize its existing space, store products longer, and improve its workflow processes.

Additionally, the adoption of self-storage facilities has also witnessed an uptick. Take the case of a popular logistics company that expanded to include self-storage units in its various locations. Optimizing additional costs with self-storage units equipped with video surveillance, they could provide personal and business storage solutions in a secured setting.

These examples highlight the extent to which commercial storage requirements can be mapped effectively to warehouse storage solutions. Despite being diverse, they share the common thread of clever space utilization and storage system innovation. By learning from their experiences, businesses can find the inspiration they need for their unique warehouse solution.

Integrating Tech with Warehouse Storage: Lexicon Tech Solutions

Warehouses are complex environments where efficient storage is just one piece of the puzzle. To truly enhance their operations, warehouses need to focus on organization and accuracy, which can be significantly improved through technology. Lexicon Tech Solutions specializes in maintaining, repairing, and providing refurbished technology specifically for warehouses aiming to upgrade their storage, organization, and overall efficiency.

Lexicon stands at the forefront of tackling the intricate challenges of warehouse operations by integrating cutting-edge technology. Their expertise helps warehouses navigate the complexities of modern tech integration, propelling them into a new era of operational sophistication.

Lexicon operates from a substantial 75,000-square-foot facility, reflecting its commitment to delivering high-quality and durable technology solutions. This facility, which meets international standards, underscores Lexicon’s dedication to excellence and enduring solutions in technology maintenance.

A key offering from Lexicon is RepairEngine®, a cloud-based maintenance management platform. This platform is a device repair tracking system that delivers real-time updates on the status of your devices in repair or deployment. This allows warehouses to proactively manage their repair and maintenance needs, staying ahead of potential issues.

Lexicon Tech Solutions makes sure that your devices are running smoothly for overall enhanced warehouse storage management. Their unique combination of technological savvy and in-depth understanding of warehouse operations cements their status as a trusted partner and provider of solutions. Lexicon’s approach goes beyond just meeting storage needs; they strive to create intelligent storage solutions tailored to enhance overall business performance.

In summary, optimizing warehouse storage is no longer a daunting task with Lexicon’s strategic and technological device support. By infusing efficiency, optimization, and intelligence into warehouse operations, businesses can set themselves on a path to success. With Lexicon Tech Solutions as your ally, you can move forward confidently, equipped for the future of warehousing.