Guest Blog from Six15: Improve Pick Rates without Breaking the Bank

Lack of business case prevents adoption of innovation in supply chain operations.

Virtual presentations and remote cocktail hours were replaced with hands-on demonstrations and face-to-face conversations with the leaders, innovators, and backbone of the supply chain at MODEX 2022. This year, the industry’s largest trade show focused on pandemic-driven supply chain disruptions and the resulting challenges – a staggering interruption in product availability, labor shortages, and increased customer demand.

The pandemic requires innovation to mitigate the challenges facing warehouse operations and prepare for future disruptions within the global supply chain. Innovations in digital twin technology, driverless vehicles, drones, and robotics can answer the demand for skilled workers. Cloud computing and IoT offer an end-to-end holistic approach to migration.

Solutions such as these have high chances of transforming a struggling operation into a well-oiled machine. The question is, when? How long will integration take from start to finish? What interruptions will the operation face during migration? Is there an ROI in sight?

As an intense sense of urgency drives warehousing and supply chain leaders forward, speed to adoption is critical in the decision-making process. Innovations designed to address the strains on supply chain operations must fit into existing infrastructure without interrupting already challenged operations. In MHI’s recent analysis in partnership with Deloitte, “Supply Chain Disruption Fuels Investments in Technology”, industry leaders acknowledge the lack of a clear business case as the number one barrier to adopting these innovations.

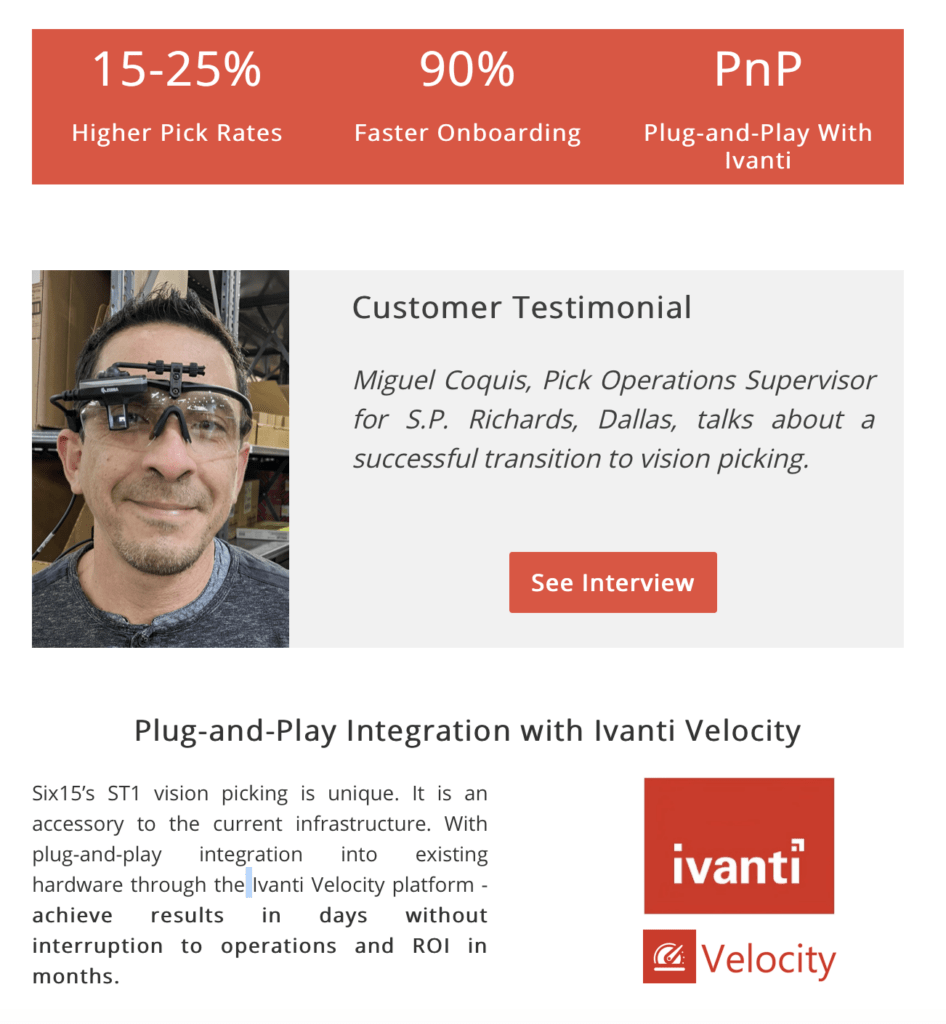

Traditional methods of order picking require wasted motions and are not handsfree; whether it be pick to light, pick with paper, or pick with handheld, the need for an order picker to “remember-recall-act” places a high cognitive load on the picker, resulting in mental fatigue, error rates, and reduced productivity. With vision picking, the relevant information is persistently displayed in the picker’s field of view. Eliminating the need for “remember-recall,” significantly reduces mental fatigue, instantly improves pick rates by 15-25%, reduces errors to near zero, and dramatically improves employee satisfaction.

Six15 ST1 Vision Picking for Faster Pick Rates

Our team of experts will HUD-enable your Ivanti Velocity Terminal Emulation or Web Browser, and return a gains report at the end of the trial.